Innovative Sorting Solutions for Snacks

Advanced optical quality control for your product.

Xcalibur

With its advanced optical object recognition, the Xcalibur is one of a kind. Xcalibur does more than just sort. It classifies. On the basis of colour, length, shape and structure, the Xcalibur can scan and arrange objects and remove them using intelligent pneumatic ejection. And it does so more quickly, carefully and safely than its competitors.

Intelligent puffing

Xcalibur

Where other machines have a standard blowing system, the Xcalibur uses a patented technology involving smaller, directed air pulses that are fully adjusted to the specific object.

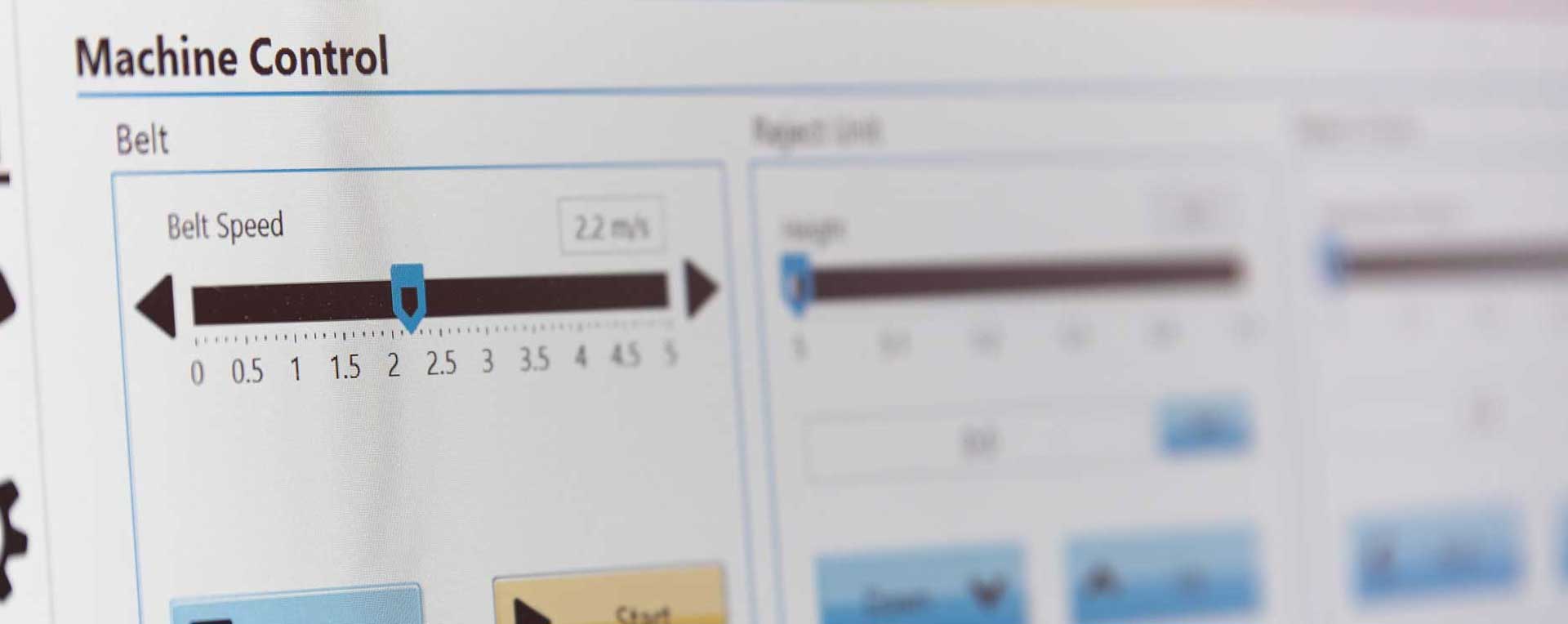

Belt speed

Xcalibur

The Xcalibur's conveyor belt reaches a speed of up to 5.2 metres per second. This raises production capacity and helps with distribution.

Sorting - Xcalibur

Advanced quality control for your optical sorting process.

E-Select - Refurbishment

Breathing new life into older machines – OptiServe’s speciality.

Reclaim - Glide

A handy cutting system that reduces your waste heap and increases your yield by as much as 70%!

Industries

Food

Potato products

Sorting sliced potato products

- Chips

- Cubes

- Slices

- Wedges

- Rösti

- Crisps

- Potato flakes

Crustaceans, shellfish & fish

- Dutch shrimps

- Mussels

- Cockles

- Red tuna flakes

Nuts, grains & seeds

- Almonds

- Sunflower seeds

- Pumpkin seeds

Fruit

Freshly cut fruit or dried fruit

- Apple cubes

- Apple wedges

- Pineapple cubes

- Peach cubes

- Frozen strawberries

- Dried prunes

- Dried dates

- Dried apricots

- Dried cranberries

- Raisins

- Cherries

Sweets

Based on colour, shape and structure

- Gummy bears

- Marshmallows

- Gums

Vegetables

- Baby carrots

- Carrots ø 0-35mm

- Green beans

- Peas

- Sweetcorn

- Mushrooms

- Sliced iceberg lettuce

- Sliced onions

- Leafy vegetables

Other

- Animal feed/pet food

- Rock salt

- Sea salt

OptiServe Xcalibur

The sorting machines of that time had limited functions and numerous problems. After several successful years with the E-Select, OptiServe wished to develop a new machine that could perform even better, with a strong emphasis on sustainability, but also with a view to efficiency and optimised production capacity. The idea was to create a sorting machine with higher capacity, a lower error rate, less waste production and less energy consumption. As an ambitious entrepreneur, OptiServe’s founder Antoine wanted to develop the basic platform for all future applications.

OptiServe was able to take its plans for a better sorting machine forward. Through the expertise of the University of Wageningen (WUR Food & BioBased Research) combined with the practical experience of OptiServe, we created a machine that could do everything that an ordinary sorting machine couldn’t do.